What grenade manufacturing teaches us about mistake proofing?

Most people rely on ‘detection’ as a way to pick up mistakes that have been made, but detection is a particularly ineffective way of mistake proofing your work. It’s too easy for mistakes to slip through the detection net and get picked up by your customers!

‘Checking’ is just one of the synonyms for mistake detection and what many people don’t know about checking is that the more checks you introduce, the more ineffective they become.

This is because the lines of accountability for quality become blurred. Be honest, how much effort do you put into something if you know it’s going to be checked by someone else? Probably not as much as you would if no-one else was going to check it. See what we mean?

“Mistakes are proof that you’re trying”

– Unknown

What's the alternative?

Many organisations are turning away from detection and moving towards mistake prevention.

Let’s take word processors as an example. Years ago, word processors would underline spelling mistakes for you to correct – this is classic detection. It shows you the mistake but relies upon you doing something to correct it, therefore documents could still exist with poor spelling.

My word processing package now corrects most of my spelling mistakes for me; I can even program it to recognise my most common spelling mistakes and correct them. This effectively prevents the mistake from becoming a defect.

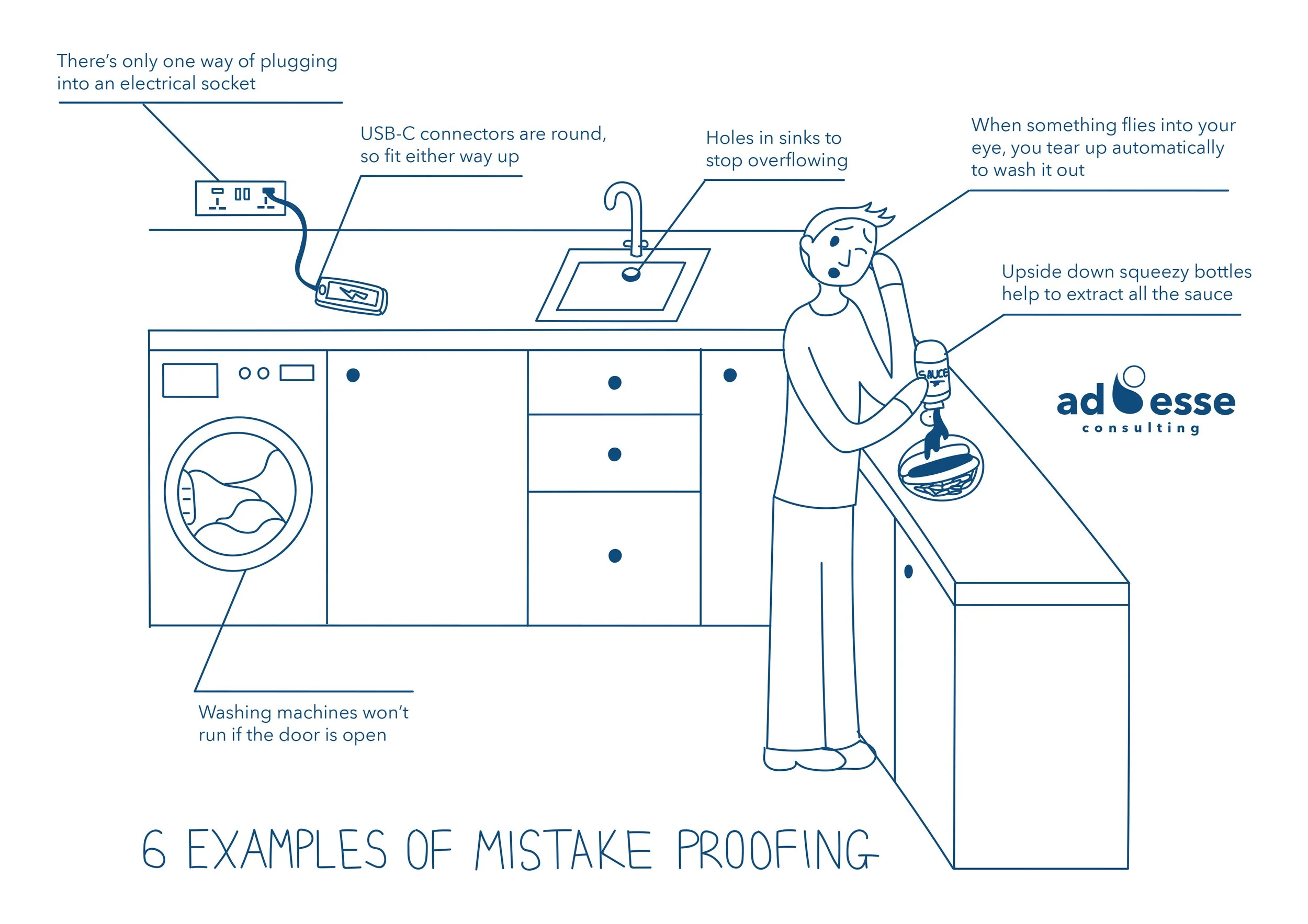

See the infographic below for more brilliant examples of mistake proofing in action:

An explosive mistake

Let me give you an example of where mistake detection failed and was replaced with effective mistake prevention.

Set up during WWII, grenade manufacturing plants played an important part of the war effort. Sadly, fatal accidents happened. Hand grenades were sometimes processed with missing pins; as a result, these pin-less grenades were sent down the manufacturing production line, eventually exploding and killing anyone nearby.

To prevent from this happening, the manufacturer introduced two inspectors for each operator on the production line. Even with these inspectors in place, a grenade was still sent down the line without a pin, killing a worker.

Another solution was needed. Instead of introducing yet more detection, the manufacturer implemented a new rack system which required the grenade to be hung by the pin before it could be sent down the production line.

The result: No inspection, but 100% certainty that the mistake would not happen again!

If you would like help with your mistake proofing, ask Ad Esse. Email hello@ad-esse.com.